"Marching Towards Excellence with United Efforts, Soaring Together to Create Brilliance." The first company-level improvement presentation meeting of DongGuan Southern CIMC Logistics Equipment Manufacture Co., Ltd. for the year 2023 was successfully held on March 16, 2023, in the VIP2 conference room on the third floor of the Comprehensive Building. This improvement presentation meeting, which has been upheld for over a decade, continues to pass down the spark of improvement through generations of CIMC employees. Organized by the Management Planning Department, the meeting was attended by the company's General Manager, management department leaders, department managers, functional directors and supervisors, department improvement administrators, employee representatives, and others.

Before the meeting, everyone collectively watched a video clip titled "Overview of Excellence Performance Model," which provided participants with a deeper understanding of the origin of the Excellence Performance Model, as well as the company's philosophy and objectives in fully implementing the model.

Subsequently, Director Zhai Shufang from the Management and Planning Department provided a detailed report on the achievement of the Creativity and Ingenuity goals for the year 2022, as well as the goals for 2023 and the accomplishments for the months of January and February. The Creativity and Ingenuity goals for 2023 include: 1) an average of ≥6 proposals per person per year; 2) 100% participation rate; and 3) presenting and winning awards at the Group ONE Annual Conference. For the months of January and February in 2023, the company received 483 proposals, with an average of 0.48 proposals per person and a participation rate of 33.5%.

Continuing, six employees from various departments shared their insights, processes, outcomes, and experiences regarding Creativity and Ingenuity improvements. The speakers included Xiao Gang from the HSE & Administration Department, Li Xiangwen from the Quality Assurance Department, Wang Jinhang, Tan Gongfan, and Wang Ming from the Production and Manufacturing Department, and Yuan Lijuan from the Management and Planning Department.

Subsequently, Wu Gang, the manager of the Management and Planning Department, provided feedback on the six presentations. Manager Wu first commended the improvements in both content and format of the presentation, highlighting that South China Zhongji has upheld the tradition of improvement presentations for 16 years. The company is among the earliest within the group to initiate such presentations, which greatly aids in fostering an atmosphere of improvement. This year, the company is fully embracing the model of Excellence in Operations, with innovation being a crucial component. The "Three Musketeers" of improvement activities are also a part of this innovation. Every department should delve deeper into promoting these activities and focus on fostering skills, showcasing achievements, shaping the culture, and nurturing talents. The presence of new faces in this presentation, along with the increased participation from various departments, indicates that our participation rate is improving. Manager Wu then provided detailed comments on each of the six proposals, evaluating their improvement content, effects, and insights. He emphasized that these improvements closely align with the work environment, ensuring safety, efficiency, quality, and cost improvements.

In order to further promote the "Three Musketeers" of improvement activities, this presentation included a special segment for sharing ONE small group and TBP (Total Business Performance) topics. Representatives from the Production and Manufacturing Department's "Innovators 2.0" ONE small group, Li Zhe, Wang Liangcheng, and Wu Lin, shared their improvement project on "Reducing the Occurrence Rate of Longitudinal Welding Defects in Door Panels." Additionally, Zhen Zhongping from the Product Technology Center presented on the improvement topic "Enhancing the Support Structure for the Top Corner of the 45-Foot Ultra-Wide Series Container's Intermediate Column."

Assistant to the General Manager, Yang Jun, provided feedback on the aforementioned ONE small group and TBP topics. Mr. Yang firstly praised the ONE small group activities for their expansion beyond the immediate team, reaching out to related teams laterally. He also emphasized the importance of implementing improvement strategies into hardware, such as fixtures and equipment, to proactively prevent issues through pre-checks rather than post-inspections. He expressed the hope that more individuals would master TPS (Toyota Production System) tools and proficiently utilize the "Eight-Step Method."

Subsequently, Manager Wu Gang from the Management Planning Department and Assistant to the General Manager Yang Jun took the stage to present trophies and commemorative prizes to the six individuals who shared their creative improvement proposals, the ONE small group representatives, and the TBP topic presenters. They also posed for a group photo to mark the occasion.

In order to foster a more conducive atmosphere for improvement and encourage everyone's participation, this presentation meeting introduced a special "Most Popular Award" for creative improvement proposals. Through pre-meeting voting, the individual with the highest number of votes received the award. Ultimately, Wang Jinhang from the Production Manufacturing Department won the award with a 65% vote rate. Manager Liu Changfu from the HSE & Administration Department presented him with a commemorative prize, and they took a photo together to commemorate the moment.

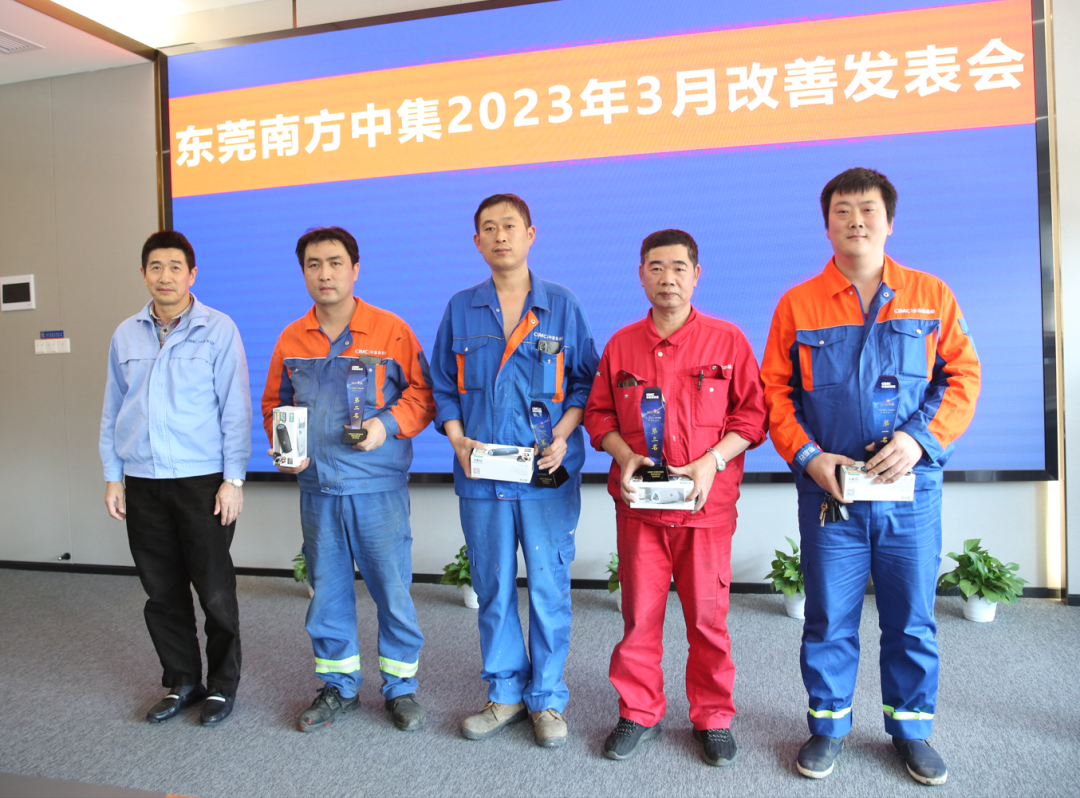

Furthermore, during this presentation, special recognition was given to those who demonstrated outstanding performance in the 2022 Creative Idea Campaign. Awards were presented to the top three individuals with the highest number of creative idea proposals in 2022, the top three teams with the highest average number of proposals per team member, and the team that exhibited the best overall practices. These exceptional individuals and teams received their awards and commemorative prizes from the company's General Manager, Mr. Liu Xiaoxu, and a group photo was taken to commemorate the occasion.

Top Three Individuals with the Highest Number of Creative Idea Proposals in 2022:

(Third Place: Luo Guangzhong and Hui Jianjun, Second Place: Wang Zhibin, First Place: Zheng Jiaguo)

Top Three Teams with the Highest Average Number of Idea Proposals per Team Member in 2022:

(Third Place: C Line Assembly Team, Second Place: B Line Assembly Team, First Place: C Line Sanding Team)

Team Best Practice Award C-line

Furthermore, General Manager Liu concluded and reviewed the event, stating that this presentation meeting has effectively showcased the efforts in creative ideas, ONE teams, and TBP projects, which is a commendable approach. As the company transitions from being a production workshop-type enterprise in the standard container sector to a "Two-Wing Soaring" full value-chain enterprise, management practices have also evolved. Moving from ISO to Lean ONE, and further to the Excellence Operating System, this progression aligns with the company's development direction.

To become an excellent enterprise, strategic planning needs to be adjusted. The company should not only achieve a balance between standard containers and specialized containers but also explore new avenues. From design to production and quality inspection, a holistic approach of planning 100%, executing 100%, and improving 100% is essential. Continuous improvement should be the foundation, focusing on getting things right the first time.The company culture is also evolving and refining. The values of having ideals, taking responsibilities, being innovative, daring to take on challenges, striving for excellence, and contributing wholeheartedly need to be perpetuated. These "2-3-4" organizational values will help enhance competitiveness.With the extensive utilization of robots and specialized machines, the production efficiency has greatly increased. However, the standards for product quality have also been elevated, demanding higher precision in incoming materials, assembly, and the professionalism of the workforce. Building upon the foundation of Lean improvement, it is crucial to propel our collective endeavors towards greater heights and to grow alongside the company.In the end, General Manager Liu expressed his optimism for the future, emphasizing that this shared journey of growth will be driven by continuous improvement, a commitment to excellence, and the united efforts of the company and its employees.

Finally, the meeting transitioned into the segment where the hosting departments for the 2023 improvement presentation meetings were determined through a lucky draw. Representatives from each department participated in the draw, and the hosting departments for each month of 2023 were decided one by one. The flag-handover ceremony was conducted by Manager Wu Gang from the Management Planning Department, who passed the hosting flag to Director Yan Zheren from the Financial Information Department, which will be responsible for hosting the event in April.With this, the successful conclusion of the 2023 improvement presentation meeting was marked. However, the journey of improvement continues to move forward, reflecting the ongoing commitment to betterment and progress.