Dongguan Southern CIMC 2023 "Safety 100" Activity and 2022 Challenge "Zero Violations, Zero Accidents" Award Ceremony Held

On February 8, 2023, Dongguan Southern CIMC welcomed the start of construction. Early in the morning before work, General Manager Liu Xiaoxu led members of the management department, department managers, and relevant HSE personnel to welcome employees back to work at the entrance of the production area gate and in front of the new office building. Welcome employees home, let's work hard together for the New Year! "A friendly New Year greeting hangs at the entrance of the employee's commute path. The company and department leaders issue return to work safety cards to the employees who resume work. The employees who resume work shall sign their personal safety commitments on the "Safety First, Zero Violations, Zero Accidents" banner in sequence.

10: The 2023 "Safety 100" launch ceremony of Dongguan Southern CIMC was officially held in August. HSE&Administration Department Manager Liu Changfu presided over the launch ceremony of "Safety 100". The company's General Manager Liu Xiaoxu, along with HSE Manager Li Zhe, members of the management department, department managers, all cultural cadres, and representatives of frontline employees from the company, attended the event, with over 200 people.

Manager Liu Changfu first introduced the origin and significance of "Safety 100", pointing out that "Safety 100" is a brilliant summary of DuPont's safety management experience as a global chemical company with over 200 years of history. Its meaning is "safety first, prevention first, zero violations, and zero accidents", with the goal of 100 days of no harm to all personnel. Today we are revisiting 'Safety 100' with the aim of ensuring that our employees can quickly recover to a tense and orderly work state after the Spring Festival through a series of safety themed activities, enhancing safety awareness and vigilance, and creating a good safety culture atmosphere. Consolidate lean safety foundation management, ensure the solid implementation of the company's safety management system on site, enhance on-site safety independent management and professional supervision level, and avoid or even eliminate safety accidents. Then, a detailed introduction was given to the implementation plan of the company's 2023 "Safety 100" series of activities, requiring all departments, workshops, production lines, and teams to conscientiously implement all work according to the company's "Safety 100" activity plan guidelines after today's launch ceremony, to ensure the expected results are achieved. The HSE&Administration Department will continuously supervise, guide, and inspect the implementation of various activities from a specialized perspective.Subsequently, General Manager Liu Xiaoxu gave a mobilization speech and announced the official launch of the "Safety 100" activity in 2023. Mr. Liu pointed out that in 2022, the company adhered to the development strategy of "two wings flying together", made timely adjustments to the organizational structure and management mechanism, and established the HSE committee execution agency, namely the HSE&Administration Department. A three-level safety management mechanism has been established based on the safety committee system management, dedicated safety department supervision, and departmental independent safety management. Everyone fulfills their respective responsibilities and collaborates closely with multiple departments to achieve the established goal of reducing annual safety accidents by 50% and successfully passing the group's annual HSE compliance audit. In 2023, the company will implement the 12 word work policy of "two wings flying together, seeking progress while maintaining stability, and excellent operation" to cope with the severe fluctuations in the standard box market, vigorously develop special box business, and continuously improve operational management level. HSE is the foundation of enterprise survival and an inevitable requirement for social progress and enterprise upgrading. 2023 is the second year for the company to implement HSE three-level safety management. The overall requirements for the company's HSE work are to standardize the environmental protection, occupational health, and safety management systems, continue to strengthen the three-level safety management mechanism based on autonomous safety management, safeguard production, and assist in achieving the company's annual business goals. Require cadres and employees at all levels to actively enhance safety awareness and awareness while maintaining correct safety positions, and proficiently master the core tools and methods of "9+8" and "eight step method". In particular, strengthen team autonomy in safety management through local safety assessment and demonstration team construction. The company will spare no effort in resource investment and provide strong support. At the same time, it will support the cultivation of HSE talents at all levels, actively apply for secondary standardization certification and the group's HSE bronze medal to meet the standards, and apply for a national green factory, so as to take the company's HSE management to a new level.

Subsequently, under the leadership of General Manager Liu Xiaoxu, all departments orderly passed through the safety gate and collectively shouted safety slogans, in this way to arouse and strengthen the attention of all employees to safety production, and to ensure consistency between words and deeds and unity of knowledge and action through practical actions.

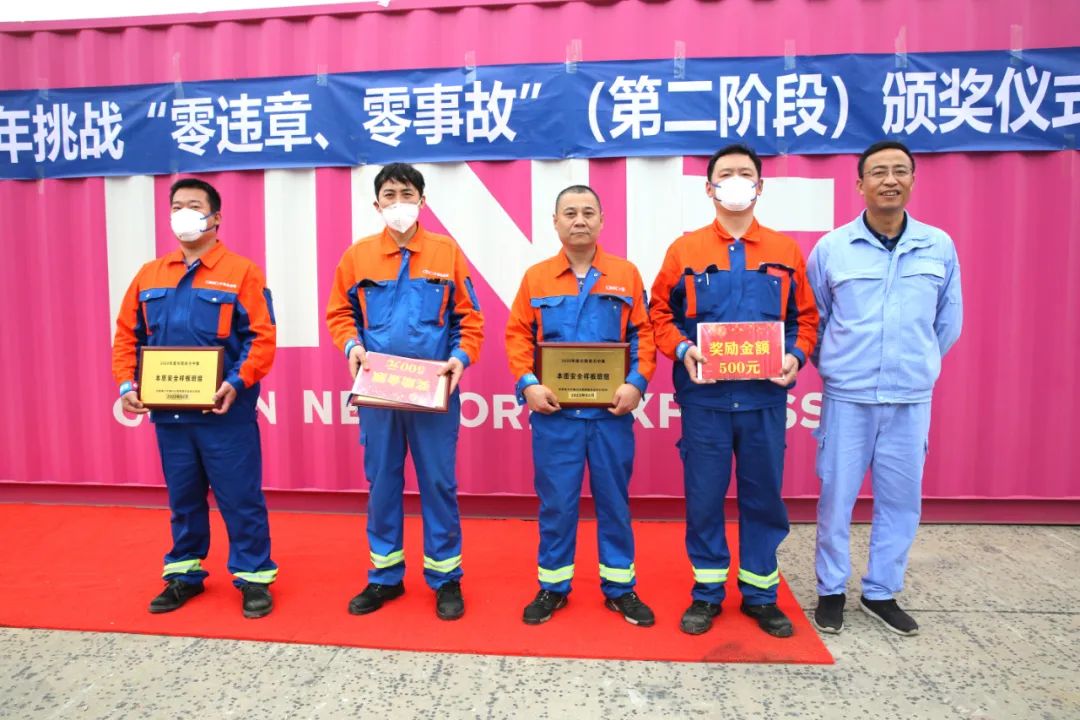

All personnel have passed through the safety gate and a sequence of teams from various departments participated in the 2022 Challenge "Zero Violations, Zero Accidents" safety award ceremony. May October 2022 coincides with the scorching heat of the year, and this period is also a critical period for our production line to gradually increase production after technological transformation, move towards target production capacity, continue to break through, and ultimately stabilize. Objectively, the combination of high temperature weather and fast-paced production rhythm poses a serious challenge to on-site safety production. In order to promote the further implementation of the HSE responsibility system, actively create a Intrinsic safety working environment, especially promote the improvement of the independent safety management ability of the production line of the production department and the grass-roots units of teams and groups, effectively curb the high incidence of safety accidents, and achieve the company's annual HSE objectives, the company has launched the "Challenge Zero Violations and Zero Accidents from May to October" activity, with the goal of results oriented, target driven and process management at the same time, Challenge the ultimate goal - 'Even if it's like a dream, it's impossible'.Through the implementation of the activity, the production line, team, and on-site safety management team were closely tied together, with consistent goals and actions, achieving the expected results. Today, taking advantage of the grand occasion of the "Safety 100" launch ceremony, we will conduct the second stage of 7.13-10.12 summary and recognition activities.The awarding ceremony was presided over by Liu Changfu, manager of HSE&Administration Department. Liu Xiaoxu, general manager of the company, Li Zhe, manager of sector HSE, and leaders of the management department presented awards to the production line of "zero violation, zero accident" activities, the "9+8" landing best practice team, and the Intrinsic safety compliance team from July to October 2022. Congratulations to the award-winning units and individuals, and we hope that all departments, production lines, and teams will closely focus on the core and key of their own independent safety management and standardized construction of safety work, solidly carry out various safety management work, and carry out the challenge of zero violations and zero accidents to the end.

After the award ceremony, all employees participating in this event took a group photo in front of the "Safety 100" background board, and the entire event ended successfully.