Equipment advantages

Dongguan CIMC South China adheres to the principles of "Technological Leadership," "Lean Planning," "High Quality and Efficiency," and "Safety and Environmental Protection." Drawing from CIMC's 40 years of experience in container manufacturing, the company extensively incorporates practices and concepts from advanced manufacturing industries such as automobiles. It combines advanced technologies and lean concepts including streamlining, mechanization, automation, standardized operations, lean logistics layout, and synchronized container handling to ensure its operations are at the forefront of efficiency and innovation.

Equipment advantages

The company integrates mechanization, automation, digitization, and intelligence into its operations. With the support of CIMC's "Dragon Soaring Plan" for manufacturing technology upgrades in the container sector, the new generation production line is more efficient and intelligent. The single-shift production capacity exceeds 440 units per 8-hour shift, with a production cycle of 60 seconds per unit. This significant enhancement in labor efficiency positions the company as a global leader in container manufacturing, often referred to as a "Dream Factory" for containers.

Equipment advantages

Over 90% of stamped parts have achieved full automation and streamlined production. In the painting and welding processes, robots are extensively used in large-scale production lines, leading to labor savings, enhanced production efficiency, improved production quality stability, and increased customer satisfaction.

Welding

Robotic welding technology is widely employed for automation in welding processes. The entire welding line utilizes 246 robots, with laser sensing used for positioning and trajectory tracking, achieving fully unmanned operation.

Painting

Over 90% of the painting stations utilize a significant number of spray painting robots. A total of 54 robots are employed in the primer, chassis, inner/outer front wall, door panel, and black painting rooms. This implementation ensures enhanced quality assurance capabilities and substantially improved production efficiency.

Specialized Machinery

To address labor-intensive processes with high manpower requirements, the company has developed specialized machinery to improve operations. For instance, a five-row automatic drilling machine is used for drilling holes in wooden floors, ensuring nail straightness. Various welding techniques, including corrugated welding, flat welding, and longitudinal welding, are employed to enhance the welding process.

Equipment advantages

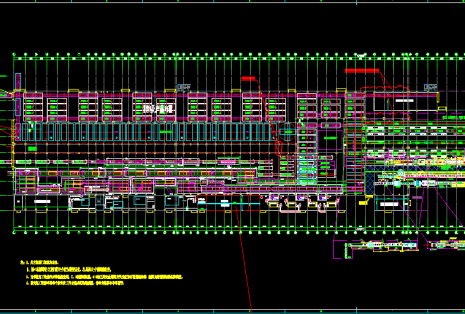

The main production line is divided into three major functional workshops: "Welding and Assembly," "Sandblasting and Painting," and "Finishing and Decoration." The total combined building area of these workshops is 58,000 square meters. 1. The Welding and Assembly Workshop is further divided into two distinct production areas: "Specialized Container and Modular Construction Zone" and "Standard and Special Container Production Zone." 2. In the Sandblasting and Painting Workshop, all products are produced in a continuous line. 3. The Finishing and Decoration Workshop is divided into two separate production areas: "Specialized Container and Modular Integration Zone" and "Standard and Special Container Production Zone."

Equipment advantages

Having the production functions of "standard special boxes, equipment special boxes, building modules" and other products: 1. Standard and Special Containers: Including 53-foot containers, 48-foot containers, 45-foot high cube containers, open-top containers, railway containers, and more. 2. Equipment Specialized Containers: Energy storage containers, data containers, environmentally friendly containers, and others designed to house specialized equipment. 3. Modular Constructions: Providing modular solutions for various types of buildings, including residential houses, commercial hotels, public facilities, and other architectural modules. The production line's versatility spans across standard containers, specialized equipment containers, and modular building solutions, catering to a wide range of applications and customer needs.

Equipment advantages

Full Coverage of Product Dimensions:The product line covers a comprehensive range of sizes, with the following maximum dimensions that encompass all specialized container products: Standard and Special Containers Dimension: Length * Width * Height = 12196 (16154) * 2550 * 2896 mm. Modular Constructions Dimension: Length * Width * Height = 18000 * 4200 * 4300 (4800) mm. These dimensions ensure that the production line is capable of accommodating various sizes of containers and modular constructions to fulfill a wide array of customer requirements.

Equipment workshop

The Equipment Workshop, which is a part of the Phase 2 specialized container production line, is divided into three major functional workshops: "Welding and Assembly," "Sandblasting and Painting," and "Finishing and Decoration." Within the workshop, various operations including decoration, equipment integration, testing, and inspections are conducted. The workshop covers an area of approximately 15,000 square meters. Additionally, the company has established a dedicated battery storage facility for energy storage container batteries, spanning around 1,000 square meters, ensuring the safe storage of the batteries.

The flatbed laser cutting equipment

The company is equipped with a large-format flatbed laser cutting machine from Han's Laser, which enables rapid and precise responses to customer requirements. Metal laser cutting provides extremely smooth and precise cutting surfaces with minimal burrs, fine seams, and minimal heat distortion. Once product drawings are finalized, laser processing can be initiated immediately, resulting in a physical prototype of the new product in the shortest possible time, thereby reducing delivery times. The equipment features a high level of automation, capable of automated edge detection and accurate positioning of workpieces. It can cut and process materials such as carbon steel, stainless steel, and aluminum, as well as handle complex irregular parts, intricate precision patterns, and lettering components efficiently.

Tube Laser Cutting Equipment

The company has tube laser cutting equipment with a wide range of applications. It can cut various profiles such as pipes, channels, angles, round bars, Ω beams, etc., and perform hole drilling, slotting, and beveling on them. The equipment features include: 1.Support for software graphics such as AutoCAD and graphic formats like DXF/AI. 2.Equipped with MES communication exchange ports and offline programming capability. 3.Ability to modify the starting position and processing direction of the graphics according to the processing requirements.

Equipment advantages

The company has precision sheet metal CNC bending machine equipment, which can accurately bend sheets with a thickness ≤ 2mm and a length ≤ 3100mm. This equipment is capable of meeting the precision bending needs of various complex sheet metal parts for special containers. Equipment features: 1.Utilizes high-performance electro-hydraulic servo hybrid drive pump control, ensuring high precision for material positioning and bending angles. 2.Equipped with (4+1) axes (Y1, Y2, X rear positioning front and rear movement, rear positioning up and down movement, worktable compensation) functionality. 3.Equipped with segmented dies and a quick clamping method for flexible and convenient operation.

Equipment advantages

Energy storage box battery equipment dedicated vehicle, used for the installation of energy storage box batteries, capable of simultaneously installing batteries on four levels. The electric push rod operates smoothly, automatically pushing the batteries into the energy storage box battery rack, ensuring efficiency and safety in battery installation. The vehicle height is adjustable, and the entire vehicle can operate automatically along the longitudinal track.

Equipment advantages

The company is equipped with two sets of charge-discharge testing equipment for energy storage boxes, capable of conducting simultaneous charge-discharge testing on four energy storage boxes. This serves as a means of product inspection, ensuring the quality compliance rate of the products.

Equipment advantages

The company has planned and constructed a small parts powder coating automated production line, designed for the powder coating of various types of small profile components used in special containers. Powder coating offers superior results compared to traditional painting techniques in terms of mechanical strength, adhesion, corrosion resistance, and aging resistance. Additionally, the process boasts high efficiency, is VOC-free, non-toxic, environmentally friendly, and results in a uniform, dense, and pore-free coating.